Q32 series caterpillar shot blasting machine includes: Q324 small caterpillar shot blasting machine, Q326 caterpillar shot blasting machine, Q3210 caterpillar shot blasting machine, Q3212 large caterpillar shot blasting machine Q3220 non-standard caterpillar shot blasting machine a variety of specifications, according to the size of the shot blasting workpiece to shape.

Q324 Small Tumble Belt Shot Blasting Machine is a new type of special shot blasting equipment designed according to user requirements, used for cleaning and strengthening castings and forgings, small spring, bearing and other workpiece. The equipment is more shot blasting, better sealing, cleaning effect, production efficiency and dust removal effect has been greatly improved, the chamber body using rolled Mn13 chamber body protection plate, single shift production service life can reach 10 years. Through shot blasting cleaning and strengthening, not only can remove the rust on the surface of the workpiece, oxide scale, sand after casting, but also can reduce the internal stress of the workpiece, improve the fatigue strength of the workpiece. The machine can be used in single machine or wiring, with high cleaning efficiency.

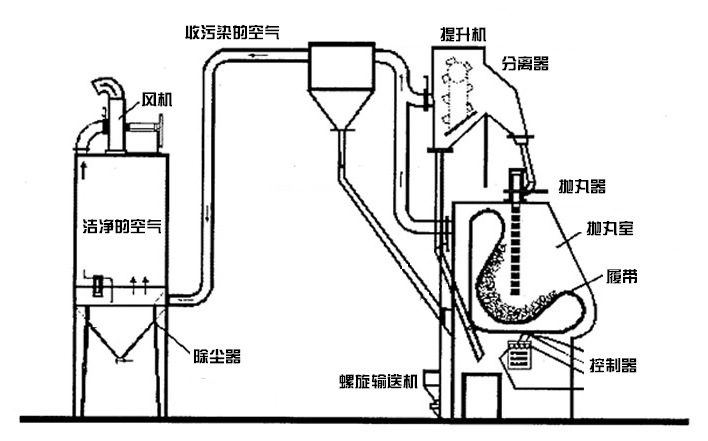

1. Shot blasting device

Native chose Q034 type belt drive form of shot blasting machine, motor and shot blasting machine installation into a whole, compact structure, small occupied area, coaxial sex strong, stable working performance, projectile through the pill after tube into the high speed rotating maru ", and from the points pills round window, through the concentrated in directional window orientation, by high speed rotating blade to undertake and accelerate, Finally, it is thrown from the end of the blade to strike and clear the surface of the workpiece.

Q324 Small Tumble Belt Shot Blasting Machine is a new type of special shot blasting equipment designed according to user requirements, used for cleaning and strengthening castings and forgings, small spring, bearing and other workpiece. The equipment is more shot blasting, better sealing, cleaning effect, production efficiency and dust removal effect has been greatly improved, the chamber body using rolled Mn13 chamber body protection plate, single shift production service life can reach 10 years. Through shot blasting cleaning and strengthening, not only can remove the rust on the surface of the workpiece, oxide scale, sand after casting, but also can reduce the internal stress of the workpiece, improve the fatigue strength of the workpiece. The machine can be used in single machine or wiring, with high cleaning efficiency.

The shot blasting device is characterized by a single impeller small disc, blade, impeller. Therefore, the moment of inertia is small, easy to start and stop, reduce the maintenance workload and production cost.

Rapid blade assembly and disassembly: because the blade of this shot blasting device is inserted from the center of the impeller, the impeller is fixed by centrifugal force in the process of rotation, so no clamping tool is needed. When removing the blade, it can be easily removed from the center of the impeller by tapping the outer end of the blade. It takes only 5-10 minutes to remove 8 blades and can check the grinding condition of the pellet wheel and the directional sleeve at the same time.

This shot blasting device blade, shot wheel, directional sleeve adopts Swiss GF.DISA production process, high chromium wear-resistant material precision casting, so that the weight error of the blade is controlled within 5 grams, greatly reduce the noise of shot blasting operation, prolong the life of easy XU pieces, beautiful appearance, delicate structure, convenient manufacturing and maintenance, low noise.

2, screw conveyor

It is composed of spiral blade, spindle, ball bearing with seat at both ends and driving pulley. It adopts the form of small diameter section distance and high speed, in order to be coaxial with the hoist at the same speed for lifting.

3, bucket elevator

It is composed of upper and lower belt pulley, belt equipped with hopper, upper drive shaft, upper tensioning adjustment device and cover shell. Its function is to bend the bottom pellet sand mixture to the top of the hoist by centrifugal force and swing down the feed pipe of the upper separator, for which a certain belt line speed is required

Native chose Q034 type belt drive form of shot blasting machine, motor and shot blasting machine installation into a whole, compact structure, small occupied area, coaxial sex strong, stable working performance, projectile through the pill after tube into the high speed rotating maru ", and from the points pills round window, through the concentrated in directional window orientation, by high speed rotating blade to undertake and accelerate, Finally, it is thrown from the end of the blade to strike and clear the surface of the workpiece.

| model | Maximum clearance weight(kg) | Maximum weight per piece(kg) | Blasting quantity(kg/min) | Side plate of diameter(mn) | The engine power(kw) | Ventilation rate(m3/h) |

| Q324 | 100 | 10 | 100 | 400 | 7 | 2000 |

| Q326 | 200 | 15 | 200 | 600 | 13 | 2500 |

| Q3210 | 600 | 30 | 600 | 1000 | 25.05 | 3500 |

| Q3212 | 1000 | 30 | 1000 | 1200 | 31.65 | 4000 |

| Optional equipment configuration according to the needs of users, automatic feeding device, unloading device, etc | ||||||

Q3210E Tumble Belt Shot Blasting Machine – automatic loading and unloadingCaterpillar shot blasting machine

Tumble Belt Shot Blasting Machine – automatic loading and unloadingAutomatic loading and unloading shot blasting machine

Q3210 Tumble Belt Shot Blasting Machine3210 Tumble Belt Shot Blasting Machine

Q328 Tumble Belt Shot Blasting Machine328 Shot Blasting Machine

Q326 Tumble Belt Shot Blasting Machine326 Tumble Belt Shot Blasting Machine